FLOWSIC100 Process Gas Flow Measuring Instrument

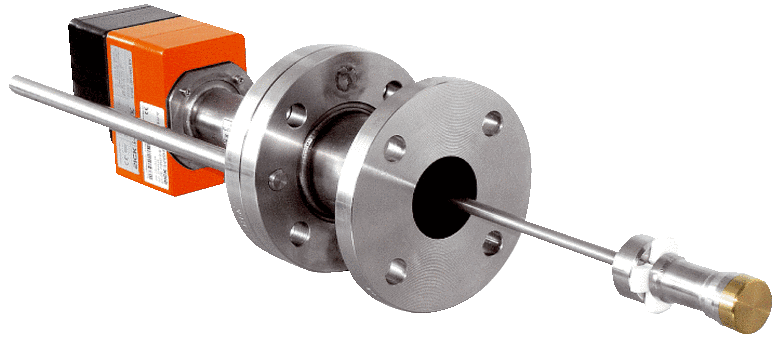

Brand: SICK CanadaWith the FLOWSIC100 Process gas flow measurement devices, measurements can be taken at pressures up to 16 bar – even in zone 2 explosive environments. The sender/receiver units are available as hermetically sealed designs made of stainless steel or titanium.

The standard system contains an MCU control unit and 2 sender/receiver units or a single measuring probe. The MCU is used for signal input and output and to calculate reference values (standardization) or mass flow. It also serves as a user-friendly LCD interface.

At a glance

- Corrosion-resistant transducer made of stainless steel or titanium

- Up to 16 bar process pressure

- Explosion-protected design for applications in zone 2 (ATEX) available

- Hermetically sealed ultrasonic transducer

- Measurements practically free of pressure loss and without influencing the process

- Automated operational check with zero and reference point test

- Reliable and accurate measurement even at low gas velocities

- Low-maintenance, as no moving parts

- Measurement is independent of pressure, temperature, and gas composition

- Does not affect gas flow, as non-contact measurement

- Approved for use in zone 2 explosive environments (ATEX)

- User-friendly operation and device diagnosis via MCU control unit and SOPAS ET operating software

Specifications

Brand

Certifications & Approvals

- CE

- ATEX

Hazardous Area

- 3G

Measured Value

- Gas Velocity, Mass Flow Rate, Volumetric Flow a. c., Volumetric Flow s. c.

- Sound Velocity

- Gas Temperature

Gas Temperature

- -40° to 260° C

Operating Pressure

- -0.5 to 16 bar

Nominal Pipe Size

- 0.15 to 1.7 m

Enclosure Rating

- IP65

Communication

- USB

- RS-232 / RS-485

- Ethernet

- Modbus

- HART

- PROFIBUS DP

- Foundation Fieldbus