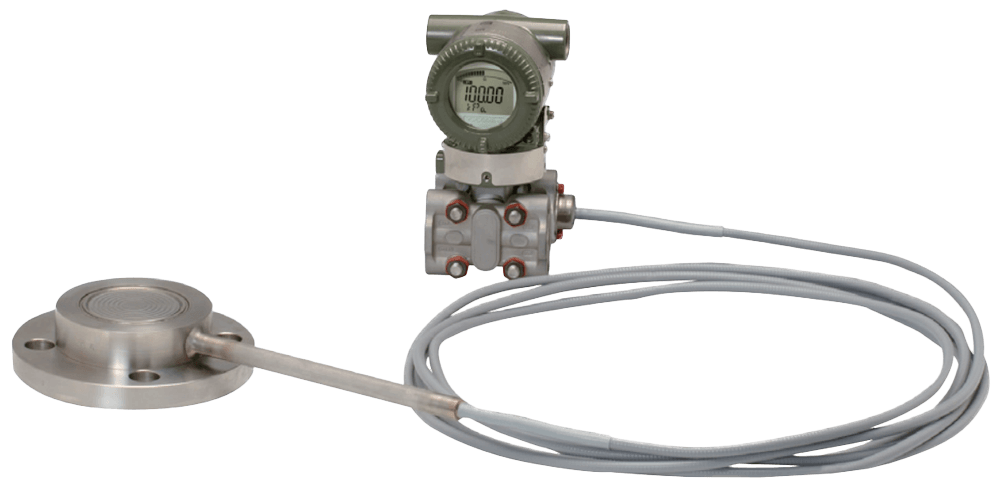

EJA438E Diaphragm Sealed Gauge Pressure Transmitter

Brand: YokogawaDiaphragm seal is used to prevent process medium form entering directly into the pressure-sensing assembly of the pressure transmitter, it is connected to the transmitter using capillary filled with fill fluid.

EJA438E Diaphragm Sealed Gauge Pressure Transmitters can be used to measure liquid, gas, or steam pressure.

EJA438E outputs a 4-20 mA DC signal corresponding to the measured pressure. It also features quick response, remote setup and monitoring via BRAIN or HART communications and self-diagnostics. FOUNDATION Fieldbus, PROFIBUS PA and 1-5 Vdc with HART (Low Power) protocol types are also available.

All EJA-E series models in their standard configuration, with the exception of the Fieldbus, PROFIBUS and Low Power types, are certified as complying with SIL 2 for safety requirement.

Features- ± 0.2% Accuracy

- 200 ms Response Time

- Exida and TUV SIL2 / SIL3 Certified

- Local Parameter Setting (LPS)

- 10-segment Signal Characterizer

- Active Capillary Fill Fluid Density Compensation

Specifications

Brand

Accuracy

- ± (0.16 + 0.004 URL/Span)% of Span (Includes Terminal-Based Linearity, Hysteresis & Repeatability) - Measurement Span A & B

- ± 0.2% of Span (Includes Terminal-Based Linearity, Hysteresis & Repeatability) - Measurement Span A & B

Alarm

- Down-Scale: -5%, 0.8 Vdc or less - for 1-5 V HART

- Down-Scale: -5%, 3.2 mA DC or less - for 4-20 mA HART/BRAIN

- Up-scale: 110%, 21.6 mA DC or more - for 4-20 mA HART/BRAIN

- Up-scale: 110%, 5.4 Vdc or more - for 1-5 V HART

Ambient Temperature Range

- -30° to 60° C (-22° to 140° F) with LCD Display

- -40° to 60° C (-40° to 140° F)

Approvals & Certifications

- Leak Test

- Material Certificate

- Pressure Test

- SIL 2 Capability for Single Transmitter Use, SIL 3 Capability for Dual Transmitter Use, IEC 61508: 2000

Approvals & Certifications

- ATEX Flameproof & Intrinsically Safe

- CSA Explosion-proof & Intrinsically Safe

- EMC EN 61326-1 Class A, EN 61326-2-3, EN 61326-2-5 (For Fieldbus)

- FM Explosion-proof & Intrinsically Safe Approval

- IEC Ex Flameproof & Intrinsically Safe

- NAMUR NE43

- PED 2014/68/EU

- PED 97/23/EC

Cable Material

- Polyethylene Insulated PVC Sheathed

Capillary Length

- 0 to 32.80 feet (0 to 10 meters)

Capillary Material

- 316 Stainless Steel

Communication

- BRAIN

- FOUNDATION Fieldbus

- HART

- PROFIBUS PA

Consumption

- 0.96-3 mA - Power

- 27 mW - Power

Current

- 6,000 A - Allowable Current

Damping Adjustment

- 0 to 100 seconds

Dead Time

- 45 milliseconds (Nominal)

Diagnostics

- Configuration Error

- CPU Failure

- Hardware Failure

- User-configurable Process High/Low Alarm for Pressure

Diaphragm Material

- 316L Stainless Steel

- Hastelloy® C-276

- Tantalum

- Titanium

Display

- 10-Segment User-configurable Signal Characterizer - for 4-20 mA Output

- 5-Digit Numerical Display

- 6-Digit Unit Display

- Bar Graph

- LCD Display

Drain, Vent Valves & Plug

- 316 Stainless Steel

Electrical Connectors

- 1/2" NPT Female - Vent/Drain Plugs

- Blind Plug

- G 1/2" Female

- M20 Female

- R 1/4" Female - Vent/Drain Plugs

Enclosure Finish

- Anti-Corrosion Coating

- Deep Sea Moss Green Paint (Munsell 0.6 GY3.1/2.0 or its Equivalent)

- Polyurethane Paint

Enclosure, Body Material

- ASTM CF-8M Stainless Steel

- Low Copper Cast Aluminum Alloy

Environmental Protection

- IP66

- IP67

- NEMA 4X

Fill Material

- Ethylene Glycol

- Fluorinated Oil

- Silicone

Flange Material

- ASTM CF-8M - Cover Flange

- JIS 304 Stainless Steel - Process Flange

- JIS 316 Stainless Steel - Process Flange, Mounting Bracket

- JIS S25C

Flange Size - 1-1/2" (DN40)

- 1-1/2" (DN40) - 150# (ANSI/JPI)

- 1-1/2" (DN40) - 300# (ANSI/JPI)

- 1-1/2" (DN40) - 600# (ANSI/JPI)

- 1-1/2" (DN40) - DIN PN 10

- 1-1/2" (DN40) - DIN PN 16

- 1-1/2" (DN40) - DIN PN 25

- 1-1/2" (DN40) - DIN PN 40

- 1-1/2" (DN40) - DIN PN 64

- 1-1/2" (DN40) - JIS 10K

- 1-1/2" (DN40) - JIS 20K

- 1-1/2" (DN40) - JIS 40K

- 1-1/2" (DN40) - JIS 63K

Flange Size - 2" (DN50)

- 2" (DN50) - 150# (ANSI/JPI)

- 2" (DN50) - 300# (ANSI/JPI)

- 2" (DN50) - 600# (ANSI/JPI)

- 2" (DN50) - DIN PN 10

- 2" (DN50) - DIN PN 16

- 2" (DN50) - DIN PN 25

- 2" (DN50) - DIN PN 40

- 2" (DN50) - DIN PN 64

- 2" (DN50) - JIS 10K

- 2" (DN50) - JIS 20K

- 2" (DN50) - JIS 40K

- 2" (DN50) - JIS 63K

Flange Size - 3" (DN80)

- 3" (DN80) - 150# (ANSI/JPI)

- 3" (DN80) - 300# (ANSI/JPI)

- 3" (DN80) - 600# (ANSI/JPI)

- 3" (DN80) - DIN PN 10

- 3" (DN80) - DIN PN 16

- 3" (DN80) - DIN PN 25

- 3" (DN80) - DIN PN 40

- 3" (DN80) - DIN PN 64

- 3" (DN80) - JIS 10K

- 3" (DN80) - JIS 20K

- 3" (DN80) - JIS 40K

- 3" (DN80) - JIS 63K

Flange Size - 4" (DN100)

- 4" (DN100) - 150# (ANSI/JPI)

- 4" (DN100) - 300# (ANSI/JPI)

- 4" (DN100) - DIN PN 10

- 4" (DN100) - DIN PN 16

- 4" (DN100) - DIN PN 25

- 4" (DN100) - DIN PN 40

- 4" (DN100) - JIS 10K

- 4" (DN100) - JIS 20K

- 4" (DN100) - JIS 40K

Flange Type

- Straight

Fluid Specific Gravity

- 0.94 to 1.92

Gasket Material

- 316 Stainless Steel (Hoop) - for Transmitter Side

- PTFE Teflon (Filler) - for Transmitter Side

Humidity

- 0 to 100% Relative Humidity - Ambient Humidity

Input Impedance

- 10 KiloOhms or more at 2.4 kHz - for Communicating Device

Load

- 0 to 1,290 ohms - for Operation - for 4-20 mA HART/BRAIN

- 0.22 μF or less - Load Capacitance

- 250 to 600 ohms for Digital Communication - for 4-20 mA HART/BRAIN

- 3.3 MH or less - Load Inductance

Load Impedance

- 550 ohms

Materials of Construction

- JIS SECC - Mounting Bracket

- JIS SUS304 Stainless Steel - Protection Tube, Mounting Bracket

- JIS SUS316 Stainless Steel - Name Plate & Tag, Mounting Bracket, Pipe

Mounting

- 2" Pipe Mounting - Transmitter

Mounting Position Effect

- Tilting up to 90° will cause Zero Shift up to 0.4 kPa

NACE & NIST

- NACE MR-0103

Nut & Bolt Material

- 316L Stainless Steel

- 660 Stainless Steel

- Carbon Steel

O-Ring Material

- Buna-N - Cover O-Ring

- Fluororubber - Cover O-Rings

Output

- 1-5 Vdc (3 or 4-Wire)

- 3.6-21.6 mA

- 4-20 mA DC (2-Wire)

Output Load

- 1 MegaOhm or Greater (Meter Input Impedance)

Power Supply

- 9-28 Vdc for General Use & Flameproof Typical - for 1-5 V HART

Power Supply Effect

- ± 0.005% Per Volt (from 21.6 to 32 Vdc, 350 ohms)

Pressure Range

- bar: -1 to 160

- kPa: -100 to 16,000

- psi: -14.5 to 2,300

Pressure Type

- Absolute

- Sealed Gauge

Process Connection Style

- Extended Typical

- Flush Typical

Process Temperature

- -50° to 310° C (-58° to 590° F)

Response Time

- 200 milliseconds (Approximately Value at Normal Temperature)

Screw Material

- 316 Stainless Steel - Zero-Adjustment Screw & Set Screws

Supply Pressure

- psi: 0 to 14.5 (kPa: 0 to 100, bar: 0 to 1) - Absolute

Supply Voltage

- 10.5-30 Vdc - Intrinsically Safe, Typical N or Non-Incendive

- 10.5-32 Vdc - Lightning Protector

- 10.5-42 Vdc - General Use & Flameproof Typical

- 16.6 Vdc Minimum - Digital Communications, BRAIN & HART

- 24 Vdc, 0 to 550 ohms Load

Temperature Effect

- ± (0.53% of Span+0.025% of URL) Per 28° C (50° F) - Ambient Temperature Effects for Capsule A & B

Update Time

- 45 milliseconds - Pressure

Wetted Materials

- 316L Stainless Steel

- Hastelloy® C-276

- JIS SUS316 Stainless Steel

- Tantalum

- Titanium

Zero Offset

- External Zero is Continuously Adjustable with 0.01% Incremental Resolution of Span - External Zero Adjustment

Documentation

Product Manuals

Certificate

Product Diagram

Specification

Technical Information

- FGP-110 5 .us.pdf 717 KB

- FGP-120 4 .us.pdf 1.0 MB

- FGP-140 5 .us.pdf 813 KB

- FGP-150 4 .us.pdf 708 KB

- FGP-160 4 .us.pdf 677 KB

- FGP-170 3 .us.pdf 627 KB

- FGP-210.us.pdf 584 KB

- FGP-220 2 .us.pdf 493 KB

- FGP-230 2 .us.pdf 756 KB

- FGP-270 2 .us.pdf 634 KB

- FGP-280 1 .us.pdf 1.1 MB

- FGP-300 1 .us.pdf 2.2 MB

- FGP-310 1st edition .us.pdf 811 KB

- FGP-340 1 .us.pdf 513 KB

- FGP-350 1 .us.pdf 451 KB

- TI01C25A05-01EN.pdf 658 KB